Welcome to the definitive sterile processing technician study guide pdf, your gateway to understanding the intricacies of this critical healthcare role. Within these pages, you’ll embark on an educational journey that will equip you with the knowledge and skills necessary to ensure patient safety and maintain the highest standards of infection control.

As you delve into the chapters of this guide, you’ll gain insights into the responsibilities and duties of a sterile processing technician, the educational and certification requirements, and the various sterilization and disinfection methods employed in the field. We’ll explore the principles and applications of each method, ensuring a thorough understanding of their effectiveness and limitations.

1. Sterile Processing Technician Role: Sterile Processing Technician Study Guide Pdf

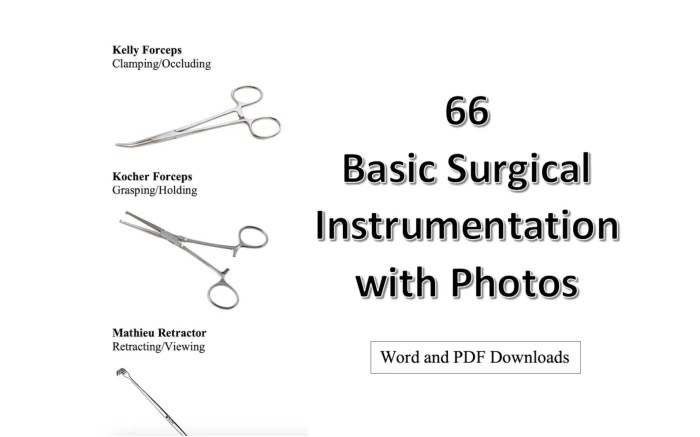

Sterile processing technicians play a critical role in ensuring the safety and well-being of patients by processing and sterilizing surgical instruments and medical devices.

Their responsibilities include:

- Cleaning, inspecting, and assembling surgical instruments and medical devices

- Sterilizing equipment using various methods, such as autoclaves, ethylene oxide gas, and hydrogen peroxide gas plasma

- Maintaining and calibrating sterile processing equipment

- Documenting and tracking sterile processing activities

To become a sterile processing technician, individuals typically need a high school diploma or equivalent and specialized training or certification. Certification programs are offered by various organizations, such as the International Association of Healthcare Central Service Materiel Management (IAHCSMM) and the Certification Board for Sterile Processing and Distribution (CBSPD).

2. Sterilization and Disinfection Methods

Sterilization and disinfection are essential processes in sterile processing to eliminate or reduce the presence of microorganisms on medical devices and equipment.

- Steam sterilization (autoclaving):Uses high-pressure steam to kill microorganisms, including bacteria, viruses, and spores.

- Ethylene oxide (EtO) gas sterilization:Uses EtO gas to penetrate and kill microorganisms, including spores.

- Hydrogen peroxide gas plasma sterilization:Uses hydrogen peroxide gas plasma to kill microorganisms, including spores.

- Chemical disinfection:Uses chemical solutions to kill or inhibit the growth of microorganisms, but does not necessarily eliminate spores.

3. Equipment Maintenance and Calibration

Regular maintenance and calibration of sterile processing equipment are crucial to ensure its accuracy, reliability, and safety.

Maintenance procedures include:

- Cleaning and lubricating equipment

- Inspecting equipment for wear and tear

- Replacing worn or damaged parts

Calibration procedures involve using certified standards to ensure that equipment is functioning within acceptable limits.

4. Quality Assurance and Control

Quality assurance and control measures are implemented in sterile processing to maintain high standards and prevent contamination.

- Documentation:Detailed records are kept of all sterile processing activities, including cleaning, sterilization, and equipment maintenance.

- Audits:Regular audits are conducted to assess compliance with established standards and procedures.

- Monitoring:Environmental monitoring is performed to detect any potential sources of contamination.

5. Sterile Processing Standards and Regulations

Sterile processing practices are governed by various industry standards and regulations to ensure patient safety and compliance.

- ISO 13408:International standard for the design, validation, and routine control of sterilization processes.

- AAMI ST79:American National Standard for Comprehensive Guide to Steam Sterilization and Sterility Assurance in Health Care Facilities.

- FDA regulations:The U.S. Food and Drug Administration (FDA) regulates the manufacture, distribution, and use of medical devices, including sterile processing practices.

6. Aseptic Technique and Microbiology

Aseptic technique is a set of practices used to prevent contamination during sterile processing.

- Sterile field:A designated area where sterile instruments and materials are handled.

- Gowning:Sterile gowns, gloves, and masks are worn to prevent contamination from personnel.

- Transfer techniques:Proper techniques are used to transfer sterile items without introducing contamination.

Microbiology plays a vital role in understanding and preventing contamination. Sterile processing technicians must be aware of the different types of microorganisms, their modes of transmission, and the methods to prevent their growth.

7. Sterile Processing Best Practices

Optimizing sterile processing operations requires adherence to best practices:

- Efficient workflow:Establish a streamlined workflow to minimize handling and potential contamination.

- Proper storage:Store sterile items in a clean, dry environment to prevent recontamination.

- Continuous improvement:Regularly review and update sterile processing practices to improve efficiency and safety.

8. Emerging Trends and Advancements

Sterile processing technology and practices are constantly evolving.

- Automated systems:Automated systems are being developed to improve efficiency and reduce human error.

- Single-use devices:The use of single-use devices is increasing to reduce the risk of contamination.

- Rapid sterilization methods:New methods are being developed to reduce sterilization time and improve efficiency.

Question & Answer Hub

What are the educational requirements for becoming a sterile processing technician?

Typically, a high school diploma or equivalent is required, along with specialized training programs or certifications in sterile processing.

What are the key responsibilities of a sterile processing technician?

Sterile processing technicians are responsible for cleaning, disinfecting, and sterilizing surgical instruments, medical devices, and equipment to prevent the spread of infection.

What are the different sterilization methods used in sterile processing?

Common sterilization methods include steam sterilization, dry heat sterilization, ethylene oxide gas sterilization, and radiation sterilization.