Stud wall parallel to joists – Parallel stud walls to joists offer a robust construction method that ensures structural integrity and versatility in various building applications. This comprehensive guide delves into the purpose, materials, construction techniques, and benefits of this technique, providing valuable insights for builders and homeowners alike.

From understanding the structural framework to exploring material considerations and step-by-step construction methods, this guide empowers readers with the knowledge to create durable and efficient stud walls parallel to joists.

Structural Framework: Stud Wall Parallel To Joists

In the realm of construction, stud walls stand as essential components, forming the backbone of interior spaces. These frameworks of vertical studs, typically made of wood or metal, provide support and define the layout of rooms, closets, and other interior divisions.

Stud Walls Parallel to Joists

When constructing stud walls, aligning them parallel to the joists is a common practice that offers several advantages. Joists, the horizontal beams that support the flooring system, provide a sturdy base for stud walls, ensuring stability and load-bearing capacity. This orientation allows for efficient transfer of weight and forces, preventing the wall from buckling or sagging under stress.

Installing a stud wall parallel to joists requires careful planning and execution. It’s akin to packing a suitcase for a journey, where each item has its designated place. Just as a traveler considers the size and weight of their luggage, the placement of studs should align with the load-bearing capacity of the joists.

In this analogy, maletas / ser / pasajero (suitcases / being / passenger) symbolizes the studs, while the joists represent the transportation infrastructure. By ensuring a harmonious balance between the two, the stud wall will stand sturdy and serve its intended purpose.

Moreover, positioning stud walls parallel to joists simplifies electrical and plumbing installations. By running wires and pipes through the spaces between studs, contractors can easily access and maintain these essential systems without compromising the structural integrity of the wall.

Material Considerations

When selecting materials for stud walls parallel to joists, several factors come into play, including structural integrity, cost, availability, and ease of installation. Different materials offer unique advantages and disadvantages, and the choice depends on the specific requirements of the project.

Wood Studs

- Advantages:Strong, readily available, cost-effective, easy to cut and install.

- Disadvantages:Susceptible to moisture damage, can warp or twist over time.

Metal Studs

- Advantages:Fire-resistant, straight and true, resistant to moisture, termites, and rot.

- Disadvantages:More expensive than wood studs, requires specialized tools for cutting and installation.

Engineered Wood Studs

- Advantages:Stronger and more dimensionally stable than wood studs, resistant to moisture, insects, and fire.

- Disadvantages:More expensive than wood studs, can be difficult to find in some areas.

Choosing the Right Material

The best material for a particular stud wall project depends on several factors, including:

- Load-bearing requirements:Metal studs are stronger than wood studs, making them a better choice for load-bearing walls.

- Moisture resistance:Metal and engineered wood studs are moisture-resistant, making them suitable for areas prone to humidity or water damage.

- Cost:Wood studs are the most cost-effective option, while metal and engineered wood studs are more expensive.

- Availability:Wood studs are readily available, while metal and engineered wood studs may be more difficult to find in some areas.

Construction Methods

Building a stud wall parallel to joists involves a series of steps that require precision and attention to detail. This section will guide you through the process, providing insights into framing, sheathing, and insulation techniques.

Framing

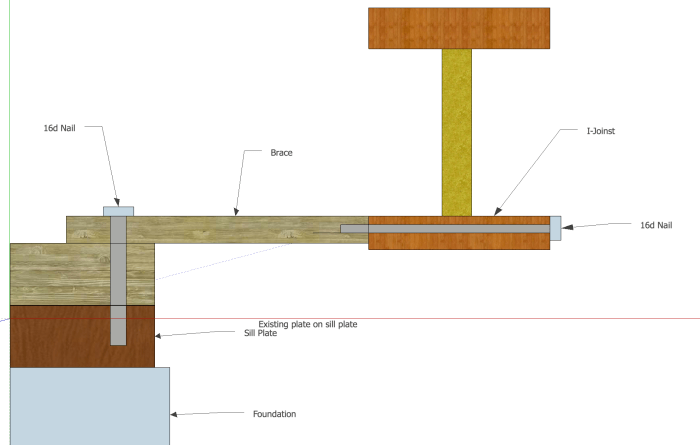

The framing process begins by laying out the wall’s location on the subfloor. Mark the positions of the studs, typically spaced 16 or 24 inches apart, and use a chalk line to snap reference lines.

Cut the studs to the desired height, allowing for the top and bottom plates. Install the bottom plate by nailing it to the subfloor along the reference line. Position the studs vertically, aligning them with the marks on the subfloor.

Secure the studs to the bottom plate using toe-nailing.

Install the top plate by nailing it to the top of the studs. Ensure that the top plate is level and square to the bottom plate. Use a level to check the vertical alignment of the studs and adjust as necessary.

Sheathing

Sheathing provides structural support and a surface for attaching drywall or other finishing materials. Cut the sheathing panels to fit between the studs, leaving a small gap at the edges for expansion and contraction.

Nail the sheathing panels to the studs, starting from the bottom and working your way up. Use roofing nails or screws spaced approximately 6 inches apart. Ensure that the panels are flush with the edges of the studs and that the joints are staggered for added strength.

Insulation

Insulation is crucial for energy efficiency and noise reduction. Choose the appropriate insulation type and thickness based on the climate and building codes. Cut the insulation to fit between the studs, ensuring that it fills the cavity completely.

Secure the insulation using insulation staples or friction fit. Ensure that there are no gaps or voids in the insulation, as this can compromise its effectiveness.

Structural Integrity

Maintaining structural integrity is crucial for stud walls parallel to joists. They bear the weight of the structure above, ensuring stability and preventing collapse.

Factors affecting structural integrity include:

Spacing, Stud wall parallel to joists

Stud spacing must be appropriate for the wall’s height and load-bearing requirements. Wider spacing weakens the wall, while narrower spacing increases material costs.

Bracing

Bracing, such as diagonal struts or plywood sheathing, provides lateral support and prevents the wall from buckling. Proper bracing is essential for walls exposed to wind or seismic forces.

Load-Bearing Capacity

The wall’s load-bearing capacity depends on the stud size, spacing, and bracing. Overloading the wall can lead to structural failure.

Recommendations for maintaining structural integrity:

- Use appropriate stud spacing and bracing for the wall’s height and load requirements.

- Inspect the wall regularly for signs of damage or weakening.

- Avoid overloading the wall or making unauthorized modifications.

- Seek professional advice from a structural engineer for any major alterations or concerns.

Applications and Benefits

Stud walls parallel to joists are widely used in various construction projects due to their versatility and efficiency. They offer several advantages, including the ability to create non-load-bearing interior walls, partition spaces, and enhance the structural integrity of buildings.

One of the primary applications of stud walls parallel to joists is in residential construction. They are commonly used to create interior walls in homes, dividing rooms and providing privacy. Stud walls are also employed in commercial buildings, such as offices and retail stores, to create partitions and define different spaces.

Benefits and Advantages

Using stud walls parallel to joists offers numerous benefits, including:

- Flexibility:Stud walls can be easily modified or removed, making them suitable for reconfiguring spaces or adapting to changing needs.

- Lightweight:Stud walls are relatively lightweight compared to other wall construction methods, reducing the overall weight of the building.

- Cost-effective:Stud walls are a cost-efficient option for creating non-load-bearing walls, as they require less material and labor than other methods.

- Improved Structural Integrity:When properly constructed, stud walls can enhance the structural integrity of a building by providing additional support and stability to the floor system.

Limitations and Considerations

While stud walls parallel to joists offer many advantages, there are some limitations and considerations to keep in mind:

- Load-bearing Capacity:Stud walls are not suitable for load-bearing applications, meaning they cannot support the weight of the roof or upper floors.

- Sound Insulation:Stud walls may not provide sufficient sound insulation compared to other wall construction methods, especially for high-frequency noise.

- Fire Resistance:Stud walls typically have a lower fire resistance rating than other wall types, requiring additional measures for fire protection in certain applications.

User Queries

What are the advantages of using stud walls parallel to joists?

Enhanced structural integrity, increased load-bearing capacity, improved sound insulation, and simplified framing and sheathing.

What factors affect the structural integrity of stud walls parallel to joists?

Spacing, bracing, load-bearing capacity, material quality, and proper installation techniques.

What is the recommended spacing for studs in stud walls parallel to joists?

Typically 16 or 24 inches on center, depending on the wall height, load requirements, and building codes.